Each type of ice cream is different in terms of consistency. Sorbet contains mostly water. Milk-based ice cream is a creamy mixture of milk, water and eggs. This makes agitator drives with large speed ranges extremely important for ice cream machines. Depending on the consistency, each ice cream flavor needs its own stirring modus. Speed-controlled, naturally. We have compiled the perfect solution with MOVIGEAR® mechatronic drives and a MOVI-PLC® controller.

About 90 tons of energy-efficiently produced scoops of ice cream per year delight the enthusiastic customers.

Thanks to our MOVIGEAR® mechatronic drive systems and the MOVI-PLC® advanced motion and logic controller,the different kinds of ice cream are always stirred perfectly and turn out deliciously creamy at the end. And all of this with an extremely low energy consumption thanks to the highly efficient drive technology.

- Energyefficient

- Silent operation

- Compact design

- Quick and easy instellation

- High Effiency

Our Project

Our Customer

Customer: Ballabeni Icecream

System manufacturer: Carpigiani-ALI S.p.A.

City: Munich (Germany)

Industry: Food industry

Application: Ice cream machine in the "transparent production"

Customer Requirements

- In addition to the temperature profile, the speed control is of utmost importance. If the beater runs too slowly, large ice crystals will form and make the finished product gritty. If the machine is too fast, the ice-cream does not get cold enough.

- At the same time, sensors have to reliably identify the ice cream becoming more solid

- The drive power has to continuously adjust accordingly

- The drive technology has to be as energy-efficient as possible, to conserve resources and the environment

- The drives must not be heard in the showcase factory

- As space is limited below the ice cream containers, space-saving and flexible drives are required

Our Solution:

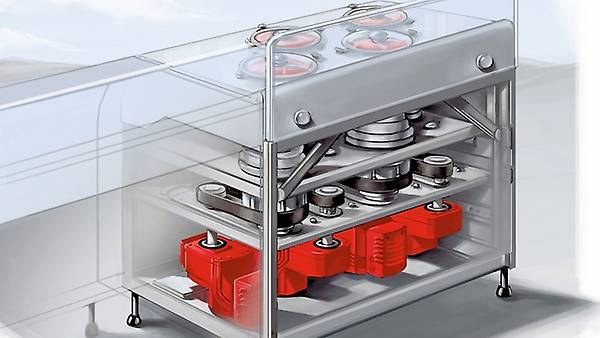

3 ice cream machines, 12 times mechatronic drive technology:

- In each machine, 4 MOVIGEAR® MGFAS2 mechatronic drive units drive the agitators of the 4 containers via toothed belts.

- In each machine, one MOVI-PLC® advanced DHR41B controller

- Sensors measuring the increasing resistance of the stirring blades when the ice cream becomes more solid

Benefits:

- Space saved due to compact drives

- Reduced installation effort due to easy and quick installation

- Reduced operating noise due to the fan-free design – ideal for use in public spaces

- Depending on the consistency, the beater runs neither too fast nor too slow, thanks to the large speed range of MOVIGEAR® and the continuous adaptation of the rotational speed by the controller

- Everything is clean as the gear unit, motor and electronics are all enclosed within a single housing and thus ideal for food production. Available in hygienic design as an option

- Extremely low energy consumption thanks to energy efficiency class IE4 allows to spend more on the best ice cream ingredients

- Reduced connected load due to the high overload capacity of the integrated motor

- The ice cream always has the desired creaminess as the controller can be programmed specifically for each customer.

- It is also possible to carry out remote maintenance and diagnostics via the Internet