-

By activating this video, Youtube will transfer data to the USA. More in our privacy policy.

MOVI-C®, the modular automation system for all-in-one solutions from a single source

MOVI-C® is the all-in-one solution for automation tasks. Whether you want to implement standards-based single-axis or multi-axis applications, particularly complex motion control applications or customized automation solutions, MOVI-C® can help you do all that and give you the scope to achieve optimum automation for new projects.

Your benefits: MOVI-C® is the all-in-one modular automation system from SEW EURODRIVE. This end-to-end solution from a single manufacturer covers all your needs – planning, commissioning, operation and diagnostics software, electronic control and monitoring devices, mechanical drives and gearmotors. There is only one place you have to go to for all the automation components you need. Naturally, all components can be fully integrated into all automation concepts, fieldbus topologies and network standards. You have complete freedom when it comes to the communication topology, as MOVI-C® harnesses all communication advantages – from PROFIBUS and Industrial Ethernet to Modbus and, in the future, OPC UA.

MOVI-C® offers automation and a whole range of benefits from a single source – specifically, a company that is both an automation specialist and a manufacturer.

The four components are:

- Engineering software

- Control technology

- Central and decentralized inverter technology and

- Drive technology

Together, these components form one complete, end-to-end modular automation system made up of devices and field units that you can combine to suit your requirements and bus topology perfectly.

Four modules – one solution: Complete automation from a single source

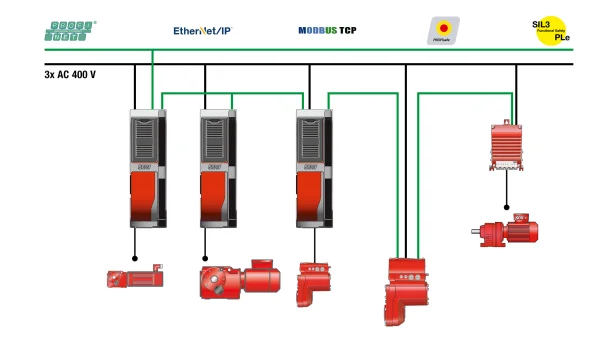

1) Single-axis automation

Typical application: Materials handling (single-axis automation)

The MOVIDRIVE® technology application inverters are directly connected to the higher-level controller via fieldbus interfaces. Predefined MOVIKIT® application modules are used to implement the drive function quickly and reliably using graphical editors. Each axis is controlled individually. A memory card in the MOVIDRIVE® application inverter is used for data management.

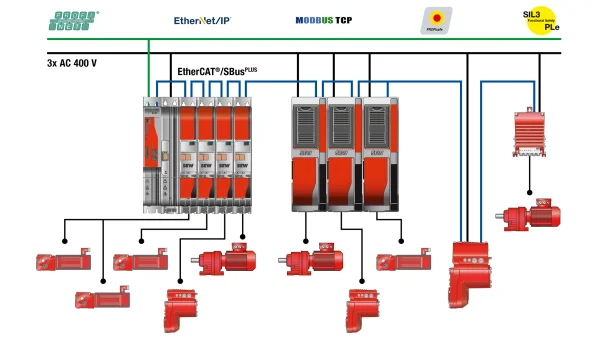

2) Motion control

Typical application: Multiple column hoists, tripod mechanisms, robots (motion control)

The MOVIDRIVE® modular and MOVIDRIVE® system application inverters are connected to the MOVI-C® controller via EtherCAT/SBusPLUS in a real-time capable manner. The MOVI-C® CONTROLLER receives setpoints for single-axis or coordinated movements from the higher-level controller via fieldbus. The MOVI-C® CONTROLLER determines the setpoints for the connected application inverters and thus performs tasks such as phase-synchronous operation, the electronic cam function and kinematic models.

Predefined MOVIKIT® application modules are used to implement the motion control drive function quickly and reliably using graphical editors. With over 50 kinematic models, a great many mechanical configurations are already covered. New kinematic models can be custom-made by SEW-EURODRIVE. A memory card in the MOVI-C® CONTROLLER is used for data management.

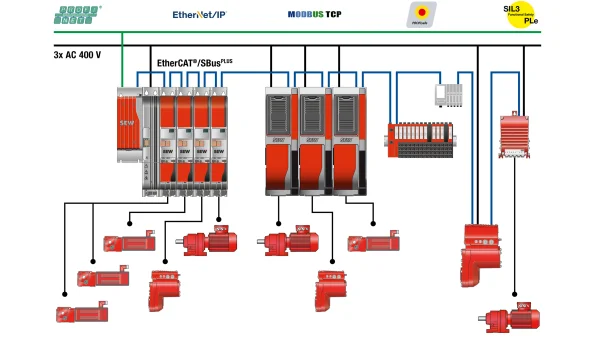

3) module automation

Typical application: Packing machines, processing machines, complex transportation tasks (module automation)

All drive functions of the motion control topology are available in the module automation topology. In addition to the graphical editors for the drive functions, some or all automation tasks of the higher-level controller can be performed easily and flexibly using the programming system (IEC 61131) in the MOVI-C® CONTROLLER. In addition to the MOVIDRIVE® application inverters, any EtherCAT® devices can be integrated for automation.

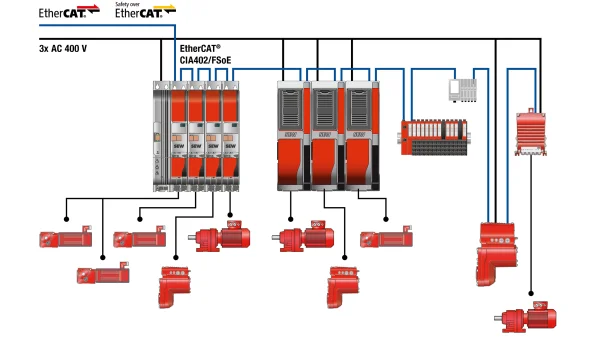

4) EtherCAT® motion slave

Typical application: Series machines with a large number of axes, kinematic calculation in the higher-level PLC (EtherCAT® motion slave)

The CiA402 profile for controlling inverters has established itself in plants with highly individual motion control functions that are calculated in the higher-level controller. For control via CiA402, the MOVIDRIVE® modular and MOVIDRIVE® system application inverters can be directly connected to the controller via the integrated EtherCAT® interface. This makes integration into the higher-level controller extremely quick and simple without any major conversion work.

CONTACT

MOVI-C® – the future of automation

Do you have any questions relating to MOVISUITE®, MOVI-C® CONTROLLER, MOVIDRIVE® inverters or drive technology?

Simply send us a message.